As the largest ecosystem on Earth, the ocean is facing an increasingly serious threat of pollution. According to statistics, about 8 million tons of plastic waste enter the ocean every year, and problems such as tanker leakage and industrial wastewater discharge are common. Traditional physical and chemical treatment methods have problems such as low efficiency, high cost, and secondary pollution, and new treatment technologies are urgently needed. Seawater electrochlorination technology uses the abundant chloride ions in seawater to produce strong oxidizing substances through electrochemical reactions, which can effectively degrade various pollutants. Bluewav's electrolytic seawater sodium hypochlorite generator has been recognized by the industry in practical applications.

1. Overview of seawater electrochlorination technology

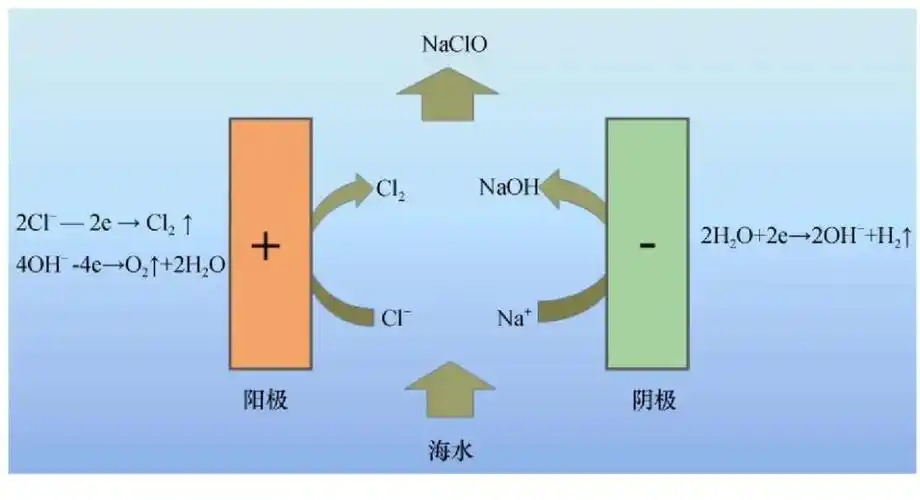

Seawater electrochlorination technology is a pollution control method based on electrochemical principles. Its core is to use the naturally existing chloride ions (Cl⁻) in seawater to produce strong oxidants such as hypochlorous acid (HOCl) and chlorine (Cl₂) through the electrolysis process. These active substances can quickly decompose organic pollutants and kill pathogenic microorganisms, and the reaction products are mainly water and inorganic salts, which will not cause secondary pollution.

Compared with traditional chlorine disinfection, seawater electrochlorination has significant advantages: first, seawater is directly used as raw material without the need to add additional chemicals; second, active chlorine is generated on site, avoiding the safety hazards of chlorine storage and transportation; third, the oxidant output can be precisely controlled by adjusting the current density to achieve automated operation. In addition, the technology has simple equipment and low energy consumption, which is particularly suitable for application scenarios far away from land, such as ships and offshore platforms.

2. Application of seawater electrochlorination in marine pollution control

In terms of marine oil pollution treatment, seawater electrochlorination technology performs well. When the electrode applies an appropriate voltage, the active chlorine generated can attack the unsaturated bonds of petroleum hydrocarbon molecules, decomposing them into low molecular weight compounds, and finally mineralizing them into CO₂ and water. Studies have shown that the degradation rate of crude oil by this technology can reach more than 90%, and the processing time is only 1/3 of that of traditional methods.

For difficult-to-degrade organic pollutants such as polycyclic aromatic hydrocarbons and pesticides, seawater electrochlorination is also effective. Active chlorine can not only destroy the molecular structure of pollutants, but also achieve deep oxidation by generating strong oxidants such as hydroxyl radicals (·OH). Experiments in a certain sea area showed that after electrochlorination treatment, the concentration of benzo[a]pyrene in water dropped from 50μg/L to below the detection limit.

When dealing with harmful algal blooms such as red tides, seawater electrochlorination can achieve rapid inactivation by destroying the membrane structure of algal cells. Comparative experiments show that the inactivation efficiency of this technology for typical red tide algae species exceeds 99%, and it will not accumulate in the marine environment like copper preparations. In addition, this technology has also achieved good application results in the fields of ship ballast water treatment and marine aquaculture disinfection.

3. Technical Challenges and Development Trends

Although the advantages of seawater electrochlorination technology are obvious, it still faces some challenges. First, the high concentration of salt in seawater has extremely high corrosion resistance requirements for electrode materials, and the currently commonly used titanium-based coating electrodes are relatively expensive. Secondly, toxic brominated byproducts may be produced when treating bromine-containing seawater, and process conditions need to be optimized to control them. In addition, the energy consumption problem in large-scale engineering applications is also worthy of attention.

Future development directions include: developing new efficient and stable electrode materials, such as graphene composite electrodes; studying advanced processes such as pulse electrolysis to improve current efficiency; exploring the combination with renewable energy sources such as solar energy and wind energy to reduce operating costs. Intelligence is also an important trend, and accurate dosing and remote monitoring can be achieved through sensor networks and automatic control systems.

IV. Conclusion

Seawater electrochlorination technology provides an innovative solution for marine pollution control. Its environmentally friendly, efficient and economical characteristics are particularly in line with the current green development concept. Chlory has been committed to the research and development of seawater electrochlorination technology. With the advancement of material science and process technology, this technology is expected to be applied in a wider range of fields and make important contributions to the protection of the marine ecological environment. In the future, basic research and technology integration should be strengthened to promote its application from the laboratory to large-scale engineering.